Key Industrial Standards for Electrical Tape Compliance

UL 510 and CSA C22.2 No. 198: Why UL-listed electrical tape is non-negotiable for safety-critical applications

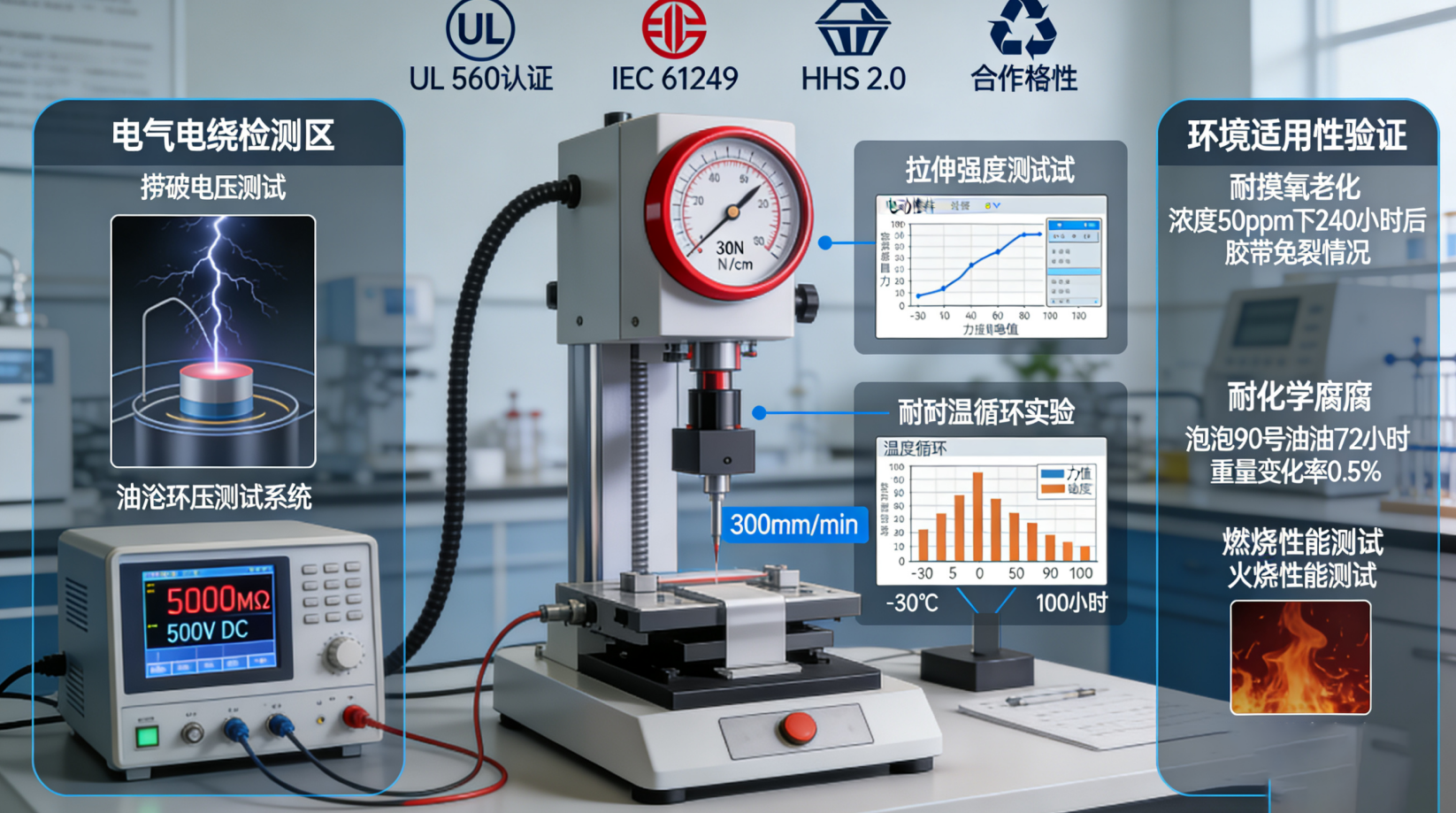

The UL 510 and CSA C22.2 No. 198 standards set important safety requirements for electrical tape in dangerous settings where failure isn't an option. When it comes to fire resistance, these regulations require tapes to withstand direct flames for at least 15 seconds before catching fire themselves. For dielectric strength, tapes need to handle over 7 kilovolts per millimeter to stop electrical failures in transformers and other critical components. Manufacturers who get their products listed by UL undergo yearly factory inspections to make sure everything stays compliant. What happens when tapes don't meet these specs? They tend to lose grip after going through temperature changes, leading to insulation problems down the road. Take motor windings for instance - using certified tape here can literally save lives since arc flashes cause about 30 percent of all electrical injuries according to NFPA data from 2023. Before purchasing, always check those UL markings and traceability numbers both on the box and actually on the tape itself.

ESD-safe electrical tape standards: ANSI/ESD S11.11 and IEC 61340-5-1 for static-sensitive environments

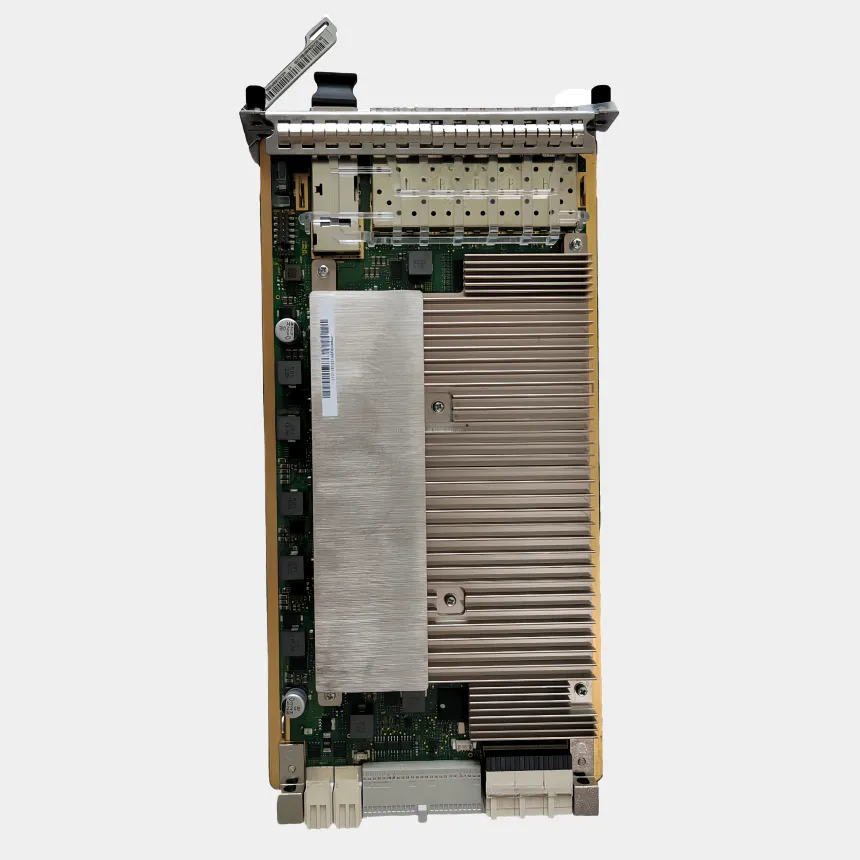

For work in electronics manufacturing, the right ESD safe electrical tape needs to meet certain industry standards such as ANSI/ESD S11.11 along with IEC 61340-5-1 guidelines. According to these rules, the surface resistance should stay under 1 billion ohms so static electricity doesn't build up dangerously. When working around delicate components on things like telecom equipment production lines, regular non-ESD tape could actually create dangerous voltages upwards of 100 volts, which is plenty enough to fry tiny microchips. Manufacturers test compliant tapes through something called triboelectric testing just to be sure they don't generate more than 30 nanocoulombs per joule. The IEC standard also looks at how well these tapes perform when exposed to different environmental factors, especially changes in humidity levels. Studies from ESDA back in 2023 found that proper ESD tape cuts down component failure rates by about a quarter in cleanrooms. Always check for those official ESD certification marks and look at the shielding specs listed on packaging before buying. And remember, swapping out regular electrical tape for circuits? That's asking for trouble in the long run.

How to Identify Certified Electrical Tape in Practice

Reading certification marks on packaging and tape backing: UL, CSA, ESD logos, and traceability codes

Before putting any electrical tape to work, check those physical markings first. Real deal electrical tape will have those embossed symbols right there on the backing material. Look for things like UL listed (that's UL 510), CSA certified (CSA C22.2 No. 198), or ESD safe (ANSI/ESD S11.11). These aren't just pretty logos either. Legit certifications come with traceability codes next to them - those alphanumeric strings that let anyone look up verification details in official databases. Take UL listed tape as an example. This stuff goes through over 16 different safety tests, covering everything from how well it handles electricity to whether it resists catching fire. And don't forget about the packaging! It needs to match what's printed on the actual tape itself. When there are discrepancies between package and product, that usually means we're dealing with knockoffs or products that simply don't meet standards.

Red flags: Unmarked, generic-labeled, or ‘UL-equivalent’ electrical tape — why it fails industrial verification

Reject unmarked tape or products labeled with vague terms like "industrial-grade"—they lack verifiable safety data. The term "UL-equivalent" is misleading, as no recognized equivalency exists for electrical safety standards. Non-compliant tape typically fails due to:

- Lack of flame retardancy: Ignites at temperatures 200°F lower than certified tape

- Inadequate dielectric strength: Risk of arc flash in circuits above 50V

- Poor adhesive performance: Degrades quickly in humid or variable conditions

A 2023 safety audit found that 84% of electrical incidents in communication equipment involved unmarked tape. The absence of certification voids insurance coverage and violates OSHA regulations—always require visible, verifiable marks.

Critical Performance Metrics for Industrial Electrical Tape

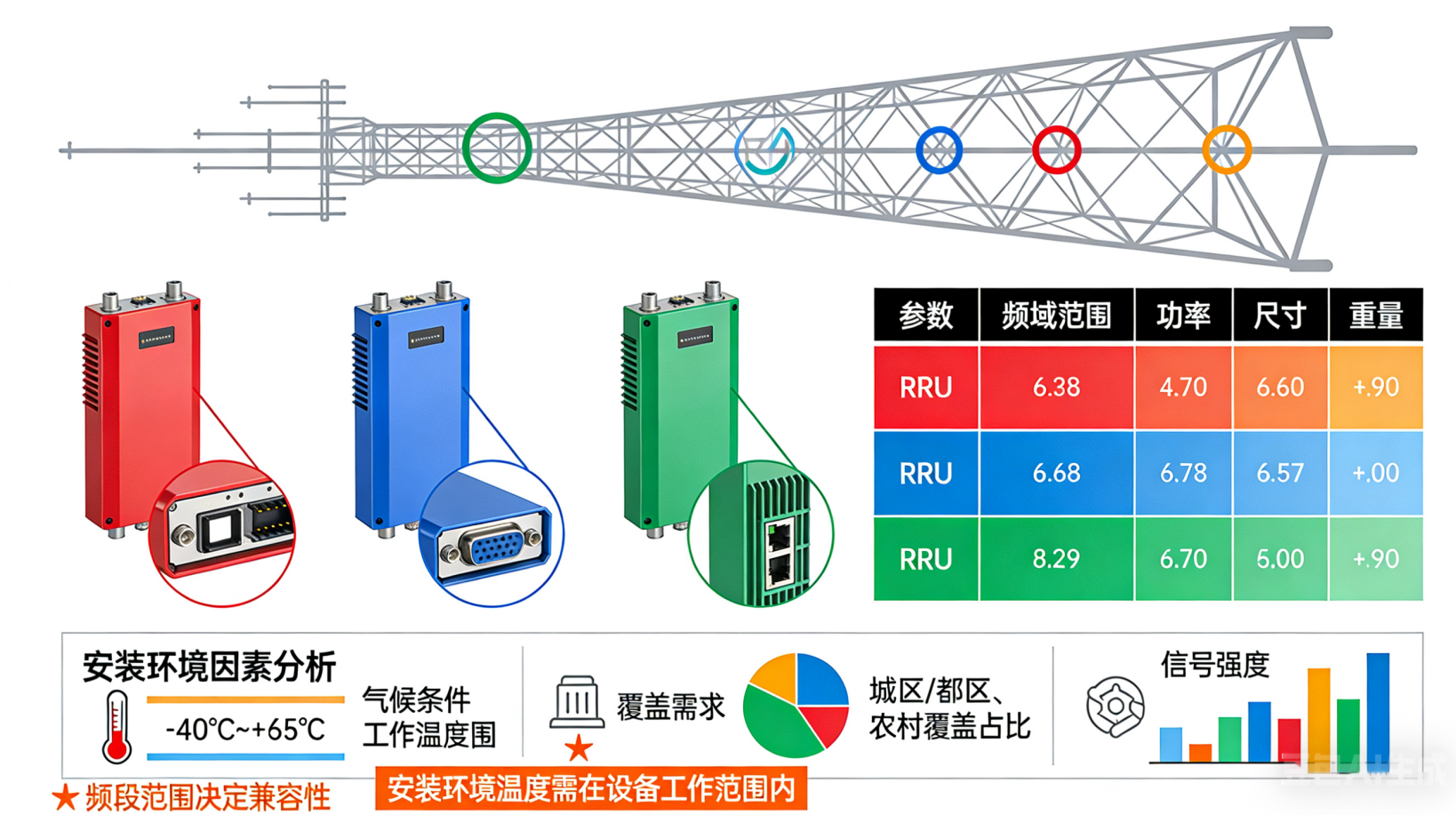

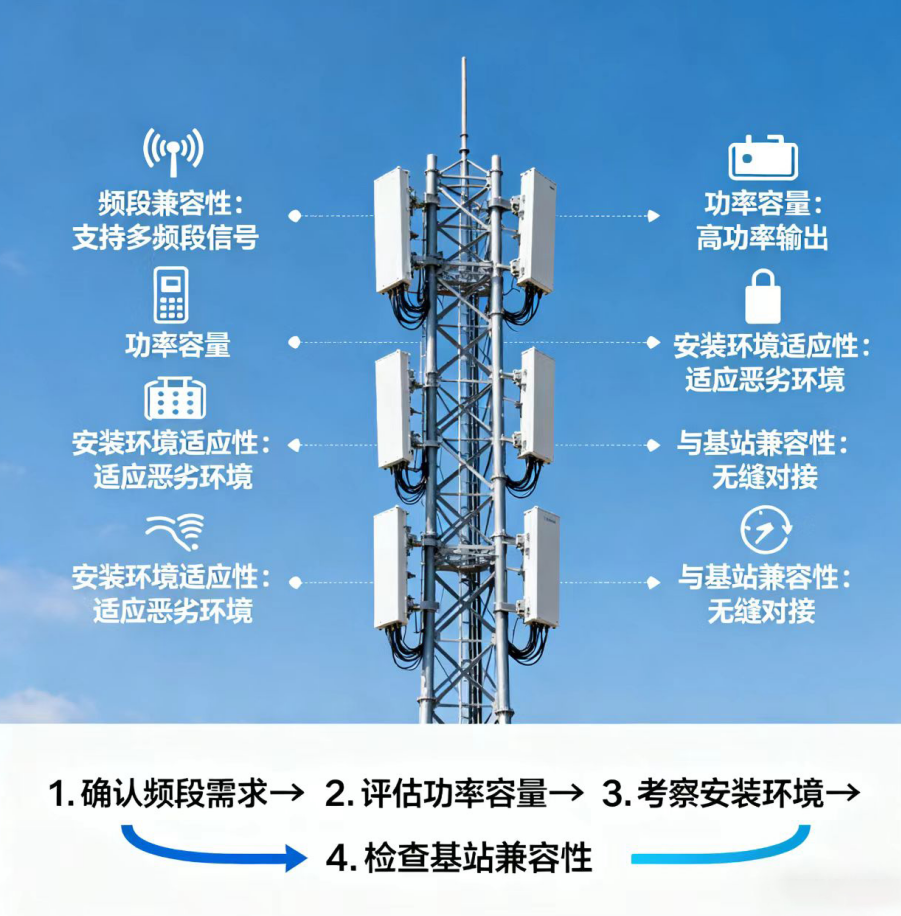

When picking out electrical tape, there are really three main specs worth checking first: voltage rating, temperature class, and dielectric strength. The voltage rating basically tells us what kind of electrical load the tape can handle safely before it breaks down. Common ratings include things like 600 volts or even 1 kilovolt. Then we have temperature classes which come in different grades - most folks work with Class B, F, or H materials. Class H is pretty tough stuff since it can handle temperatures all the way up to 180 degrees Celsius during normal operation. Dielectric strength matters too because this measurement shows how well the material resists electrical breakdown when stressed. For transformer windings specifically, look for tapes rated above 500 volts per mil thickness. Busbar connections generally call for at least Class F materials to withstand those high temps over time without failing.

Voltage rating, temperature class (e.g., Class B, F), and dielectric strength: Matching electrical tape to motor, transformer, and busbar applications

High-voltage motors (4kV+) require tapes with dielectric strength above 800 V/mil and Class F (155°C) temperature ratings to withstand thermal cycling and prevent insulation failure. Low-voltage control panels can use Class B (130°C) tape with 300 V/mil dielectric strength, balancing performance and cost.

Material comparison: PVC vs. rubber vs. silicone electrical tape for insulation, flexibility, and chemical resistance

Material selection impacts performance across key conditions:

- PVC (polyvinyl chloride): Economical with strong adhesion, suitable up to 105°C. Resists acids but degrades when exposed to solvents.

- Rubber: Offers excellent flexibility down to -40°C and strong moisture resistance, making it ideal for outdoor motor repairs.

- Silicone: Withstands temperatures up to 180°C and resists harsh chemicals, though it has lower tensile strength. Preferred in aerospace and chemical plant applications.

High-performance tapes typically operate reliably from -18°C to 105°C, ensuring durability across variable industrial environments.

Verifying Real-World Durability: Adhesion and Environmental Resistance

When working with industrial electrical tape, it needs to hold up against some pretty harsh situations. The stickiness factor matters a lot here. According to ASTM D3330 standards, good quality tape should stay put even when there's constant movement or physical pressure applied. We also test how well these tapes handle different environments. They need to survive temperature swings from as cold as -40 degrees Celsius all the way up to 150 degrees. Plus they have to withstand UV rays for over 500 hours straight and not break down when exposed to various oils and chemical solvents. Think about what happens if the tape fails on something important like transformers or those big outdoor power bars. Arc flashes are a real risk, and companies pay the price for them too. Studies show the average cost of such incidents runs above seven hundred forty thousand dollars according to Ponemon research from last year. That's why looking for tapes that come with proper certifications from independent testing labs makes so much sense for anyone dealing with electrical systems.

- Thermal endurance: Grade F (155 ° C) or higher

- Moisture resistance: Stable performance above 95% humidity

- Flexibility: Maintains integrity after 1,000+ bend cycles

Field failures are frequently linked to unverified "equivalent" products that lack documented durability under these conditions.