Environmental Resistance: UV, Moisture, and Thermal Cycling in Telecom Infrastructure

How desert UV + coastal humidity accelerate insulating tape failure in 5G base stations

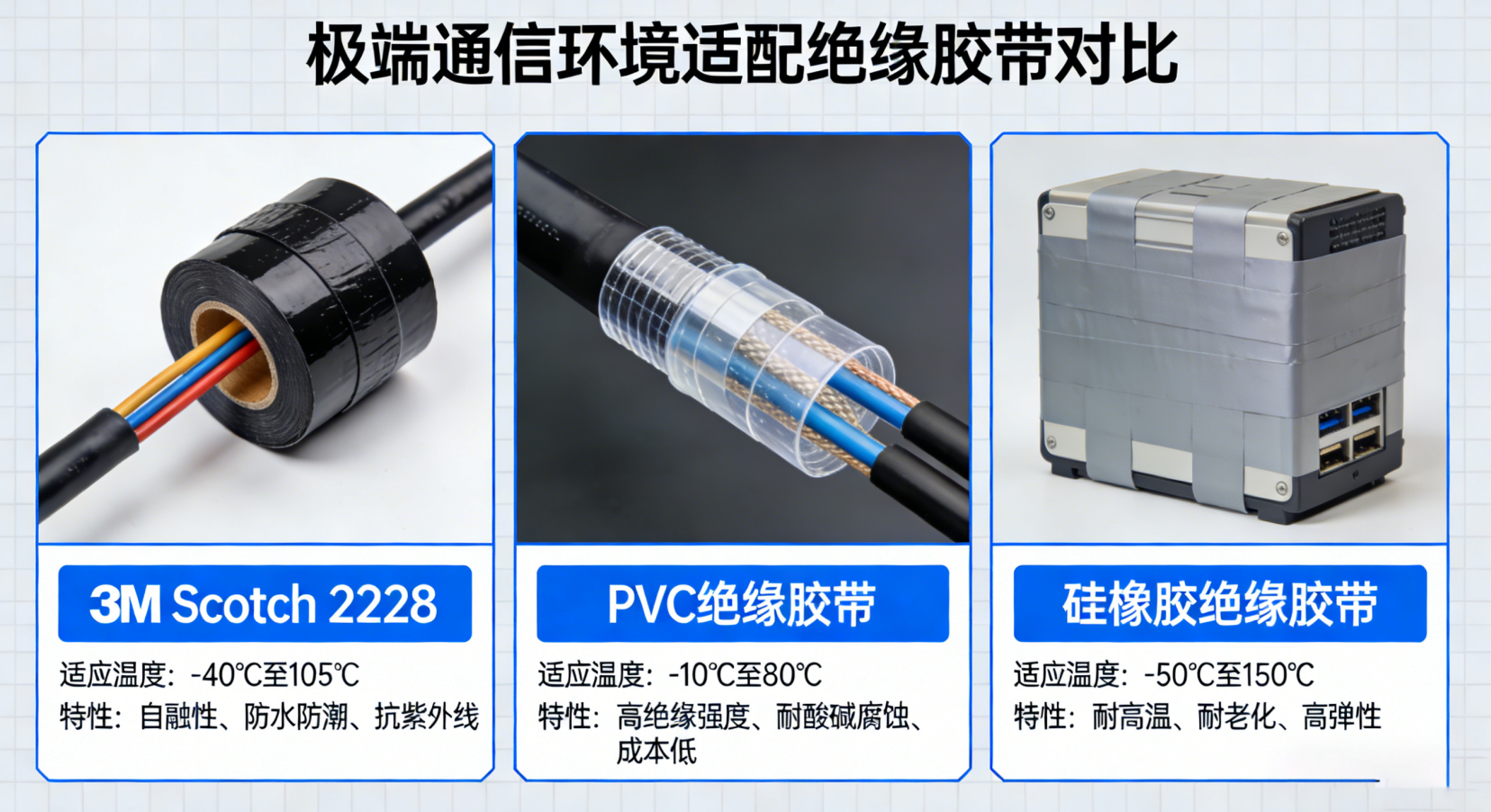

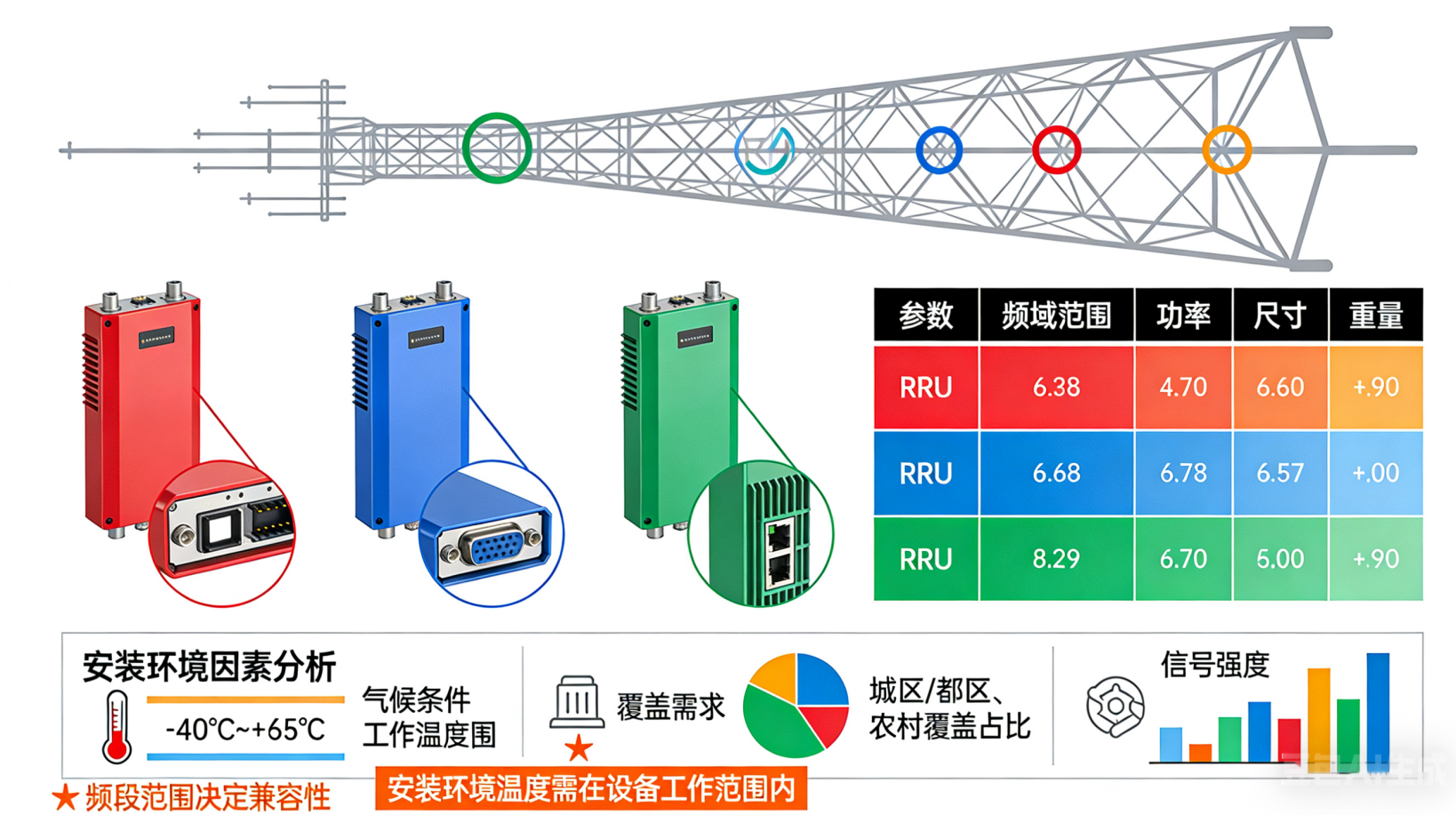

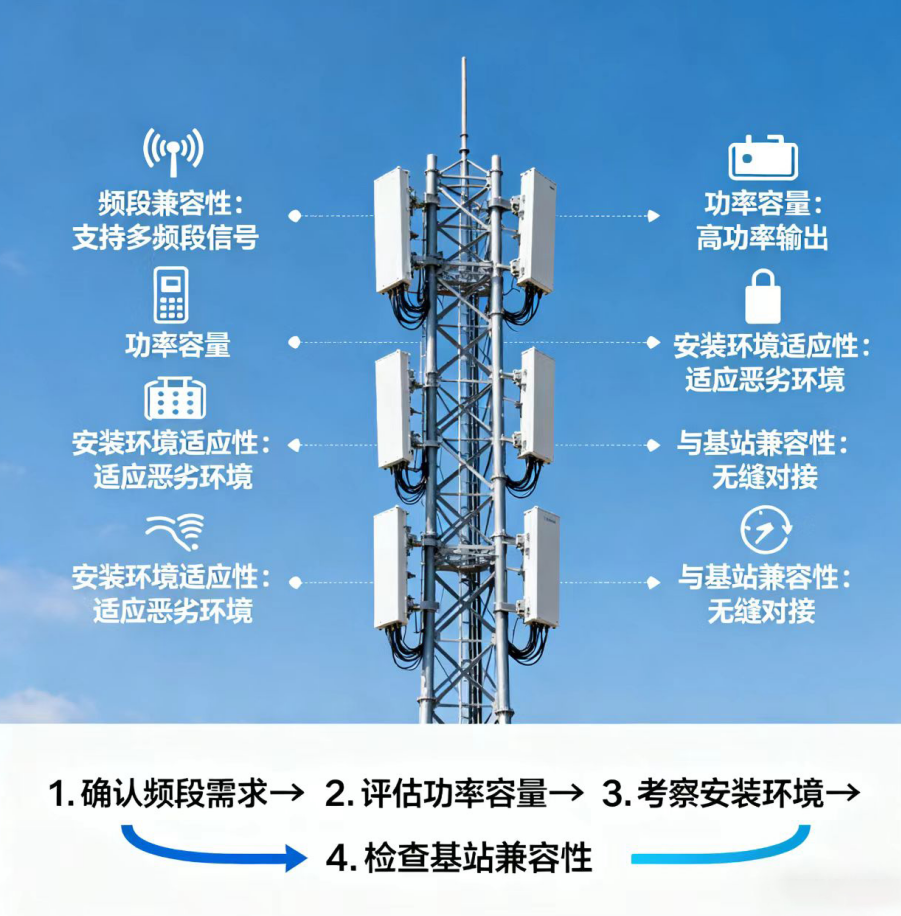

The performance of insulating tape used in telecom gear gets seriously affected when exposed to extreme weather conditions. Take deserts for instance where constant exposure to UV rays breaks down the polymer structure over time. This leads to problems like becoming brittle, developing tiny cracks, and losing structural strength altogether. Once those weaknesses appear, moisture from coastal areas can seep right in, creating pathways for ions to migrate across insulation layers. According to lab testing standards like ASTM G154 and G155, this combined effect cuts down dielectric strength by around 40% after just 18 months of operation. Temperature fluctuations between freezing cold (-40 degrees Fahrenheit) and scorching heat (up to 185F) don't help matters either as materials expand and contract repeatedly, speeding up wear and tear. Many operators have reported issues with regular tapes failing at 5G towers located in these tough environments well before their expected lifespan of six years.

Synergistic degradation: UV-induced polymer scission and moisture-assisted ion migration in insulating tape

Exposure to ultraviolet light starts breaking down polymer chains, which creates those tiny channels where moisture can sneak in. Once water gets inside, it brings along dissolved salts from places near coasts or industrial zones, and these salts help ions move between conductive materials. Thermal cycling really speeds things up though. Lab tests have shown that when all these factors combine, leakage currents jump by around three times what they would be if only one factor was at play. That's why today's insulating tapes come with special polymer bases that resist UV damage, sticky layers that repel water, plus flame retardants without harmful halogens. With these improvements, most tapes still hold onto over 90 percent of their original stickiness even after spending 2000 hours exposed to both UV rays and moisture together. They meet those important ASTM standards too - G154 for UV testing and G155 for condensation resistance.

Thermal & Flame Performance: Ensuring Reliability from -40°F to 1800°F

Polyimide (Kapton®) insulating tape for mmWave backhaul: meeting >200°C intermittent exposure demands

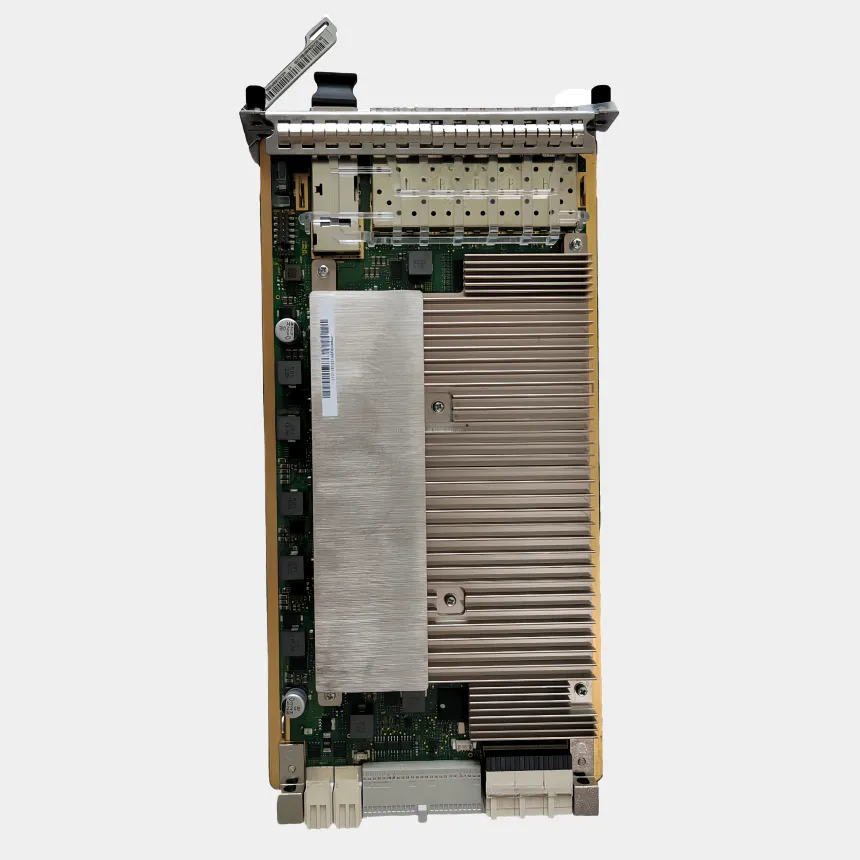

Polyimide insulating tape provides important thermal protection for mmWave backhaul systems, handling temperature spikes above 200°C (392°F) without showing signs of wear. The material's ability to withstand heat keeps electrical failures at bay in 5G base stations, especially around those power amplifiers that create so much concentrated heat. Regular polymers just don't cut it when subjected to these conditions. Polyimide stays strong through quick temperature changes, avoiding problems like becoming brittle or losing its stickiness. At only a fraction of a millimeter thick, this tape helps manage heat effectively while keeping sensitive RF parts properly insulated. Even after going through countless heating and cooling cycles, performance doesn't drop off, which means signals stay consistent even in really tough operating conditions.

Layered thermal design: mica core + silicone solid rubber overwrap for UL 94 V-0 and IEC 60332-3 compliance

When it comes to outdoor telecom infrastructure, engineers often turn to composite insulation systems that combine mica-core layers with silicone solid rubber overwraps. These systems typically earn those important dual flame-resistance certifications needed for harsh conditions. The mica part stays stable electrically even when temps hit over 1,000 degrees Celsius, acting as a real shield against dangerous thermal runaway situations. Meanwhile, the silicone coating keeps things flexible right down to minus 40 Fahrenheit and creates a solid moisture barrier something absolutely necessary for cables sitting in damp or salty air for years on end. Such designs pass both UL 94 V-0 standards where flames must go out within ten seconds max and IEC 60332-3 tests for vertical flame spread resistance. Plus, the silicone material itself tends to put out fires quickly, so flames don't travel along bundles of cable. After running through thermal cycling tests, these materials consistently perform well whether frozen solid or exposed to extreme heat levels.

Chemical, UV, and Biological Resistance: Critical for Outdoor & Industrial Deployment

Fluoropolymer insulating tape trade-offs: hydrophobicity vs. adhesion under salt-fog cycling (ASTM B117)

Fluoropolymer insulating tapes have really good water repelling properties, which makes them great at stopping electrolytic tracking problems in coastal telecom setups. Salt air gets everywhere along coastlines and speeds up those pesky ion migrations we all hate. But there's a catch. These materials naturally don't stick well because of their chemical makeup, especially when exposed to repeated salt fog tests according to ASTM B117 standards. Testing shows something interesting too. Tapes that keep water beads above 95 degrees contact angle lose about 15 to 20 percent of their sticking power after just 1,000 hours compared to those modified silicone options out there. So what does this mean? Well, if the main concern is keeping surfaces clean and dry from moisture, fluoropolymers work best. For places with lots of movement or vibration though, those hybrid silicone-fluoro mixes tend to perform better overall in real world conditions.

ROHS-compliant insulating tape paradox: reduced ozone resistance versus legacy CSPE formulations

The move towards ROHS regulations has forced manufacturers to replace brominated flame retardants, though this switch comes with some durability issues. Testing shows that today's ROHS compliant insulating tapes develop surface cracks about 30 percent quicker than old school CSPE materials when faced with industrial ozone concentrations over 50 ppm. To tackle this problem, material researchers are turning to nano clay additives which boost crosslink density while still meeting all the regulatory requirements. Lab tests simulating what happens after 15 years in the field indicate these new formulations last around 40% longer. This makes them practical solutions for telecom infrastructure and power transformers where both environmental standards and long lasting insulation performance matter most.

Mechanical Resilience & Standards Compliance Across 5G, Aerospace, and Defense Applications

Flex endurance data: silicone solid rubber insulating tape retains 92% dielectric strength after 10,000 cycles (IEC 60811-501)

Silicone solid rubber insulating tape shows remarkable durability, keeping about 92% of its dielectric strength even after being bent back and forth 10,000 times according to IEC 60811-501 standards. Regular PVC tapes typically break down completely after only around 3,000 similar cycles, falling short of what's needed for safe operation. This kind of toughness makes it ideal for areas that experience constant movement and stress, such as 5G tower connections, aircraft electrical boxes, and military equipment housings where tiny cracks from vibrations can compromise insulation over time. The tape meets both MIL-STD-202G for vibration resistance and MIL-STD-810H for environmental testing, sticking firmly even when temperatures swing wildly between -40 degrees Fahrenheit and 400 degrees Fahrenheit. This means it won't peel off during those sudden temperature changes encountered in hot desert environments or during flights at extreme altitudes. Plus, it passes the tough UL 510 fire tests and follows all ROHS and REACH regulations regarding harmful chemicals, making it straightforward to get certified for use in telecommunications networks, airplane upgrades, and various defense applications.

Table of Contents

- Environmental Resistance: UV, Moisture, and Thermal Cycling in Telecom Infrastructure

- Thermal & Flame Performance: Ensuring Reliability from -40°F to 1800°F

- Chemical, UV, and Biological Resistance: Critical for Outdoor & Industrial Deployment

- Mechanical Resilience & Standards Compliance Across 5G, Aerospace, and Defense Applications