The Critical Role of Communication Towers in Modern Network Infrastructure

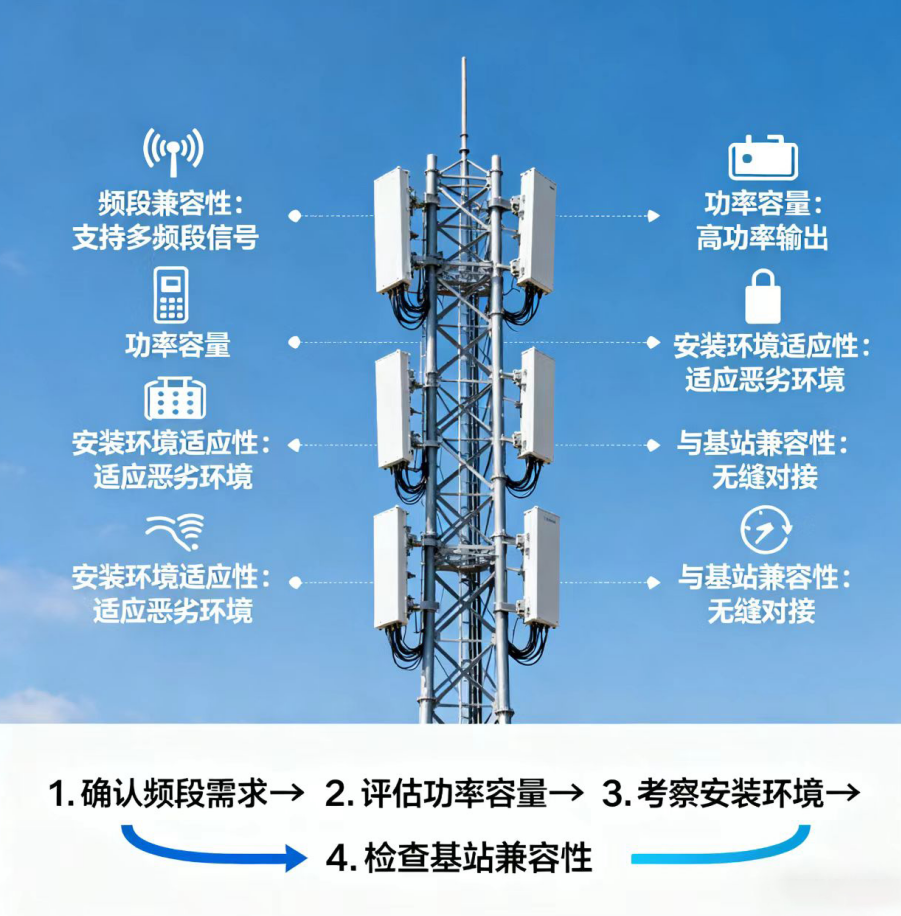

Role of communication towers in cellular and broadband connectivity

Communication towers are basically what keeps our world connected these days, handling around 80 percent of all mobile traffic globally and giving broadband access to roughly 4.3 billion people according to ITU stats from last year. These big steel masts hold up antennas that send out those radio frequency signals we rely on so much, forming the actual groundwork for cell phone networks and internet connections everywhere. As 5G technology rolls out across the country, things have gotten even more interesting for tower operators. The new standard demands far more towers packed closer together just to hit those super fast speeds above 1 gigabit per second while keeping lag times under 10 milliseconds. Pretty impressive stuff when you think about it.

Ensuring long-term reliability through infrastructure lifecycle management

Proactive maintenance is essential to avoid the $740k average cost of tower-related network downtime (Ponemon Institute 2023). Leading operators implement structured lifecycle protocols, including:

- Corrosion monitoring: Annual ultrasonic thickness testing on tower legs

- Load capacity verification: Stress analysis during 5G antenna upgrades

- Foundation inspections: Ground penetration radar surveys every 3–5 years

According to a 2023 NSMA (National Structural Maintenance Association) report, such programs extend tower lifespans to over 40 years—significantly surpassing the 25-year average for unmanaged infrastructure. Predictive maintenance alone reduces structural failure risks by 62%, while optimizing operational expenses.

Preventive and Predictive Maintenance Strategies for Communication Towers

Differences Between Preventive and Predictive Maintenance Strategies

Regular maintenance usually sticks to set timelines for checking equipment and swapping out parts. Think about those quarterly inspections or when antennas need replacing after sitting around for about five to seven years. On the flip side, predictive maintenance works differently. It looks at live data and various signals to spot problems before they become serious issues. The system might track things like how something vibrates, temperature changes, or look at past breakdown records. Industry numbers suggest this method cuts down on wasted replacements by roughly 30 percent. Over months and years, this means fewer surprises and lower costs for most businesses that implement it properly.

Scheduled Inspections and Performance Benchmarks in Tower Maintenance

Good maintenance really depends on knowing when things are going off track. For instance, most folks aim to keep signal strength above -80 dBm and make sure voltage stays stable within plus or minus 5%. Field technicians usually run infrared checks twice a year looking for signs of corrosion along those coax cables and making certain all those anchor bolts are still tight enough. The latest telecom industry report from 2023 showed something interesting too. When companies actually followed the FAA rules about checking their tower lights regularly, they saw a massive drop in problems caused by birds hitting equipment. Some places reported cutting these kinds of outages down by around two thirds just from sticking to those simple inspection requirements.

Data-Driven Forecasting Using Historical Failure Patterns

Looking through maintenance records from at least five years back gives maintenance crews a good idea about what problems keep coming up again and again. For instance, there tends to be way more rectifier failures when those big monsoons roll in. Now, if we train machine learning systems using actual environmental conditions specific to each location - think about all that humidity and those strong winds cutting across structures - these smart algorithms start getting pretty good at guessing when batteries will start failing. Some tests show they hit around 92 percent accuracy most of the time. And this isn't just theoretical stuff either. Places along coastlines report seeing their emergency repair calls drop nearly in half since implementing these predictive tools into daily operations.

Case Study: Reducing Downtime by 40% With Predictive Analytics

A communications tower company based in the Midwest installed vibration sensors along with an AI system that detects unusual patterns at over 200 locations. The tech team found that when they looked at how tilt sensors worked together with local wind conditions, their system could spot potential grounding problems around 8 out of 10 times three days before anything actually went wrong. This made a real difference too - towers now experience only about 8 hours of downtime each year instead of the previous 14 hour average, which cuts maintenance interruptions by roughly 40%. Plus, the company saves around $120,000 every year on inspections thanks to these early warnings.

Advanced Technologies Transforming Communication Tower Maintenance

Use of Drones for Efficient and Safe Tower Inspections

Drones equipped with 4K cameras and collision-avoidance systems allow non-invasive inspections of antennas, cables, and structural components, identifying issues like loose fasteners or vegetation encroachment. In 2023, Southwest U.S. operators replaced 80% of manual climbs with drone deployments, cutting inspection costs by 63%.

Thermal Imaging and LiDAR for Detecting Structural and Equipment Defects

Thermal sensors detect overheating amplifiers or power supplies, while LiDAR generates millimeter-accurate 3D maps of tower geometry. Together, these tools identify early-stage corrosion in lattice structures and misaligned waveguide connections. A 2024 analysis of 12,000 North American towers showed dual-sensor systems detected 92% of critical defects 3–6 months before traditional inspections.

AI-Powered Analytics and Digital Documentation in Maintenance Workflows

AI platforms analyze vibration data, weather conditions, and equipment logs to forecast failures with 87% accuracy (2024 Material Flexibility Study). These systems automatically generate repair checklists and update digital twin models, reducing administrative workloads by 35% for crews managing 50+ towers.

Digital Twin Technology for Real-Time Monitoring of Communication Towers

IoT-enabled digital twins replicate real-time structural stress, wind loads, and hardware performance in live dashboards. When integrated with monitoring systems, they alert operators to abnormal vibrations or RF reflection anomalies within 15 seconds of detection, enabling rapid response.

Balancing High Initial Costs With Long-Term ROI of Automated Maintenance Systems

Although advanced drones and AI platforms require an initial investment of $120k–$250k per tower cluster, operators typically recoup costs within 26 months through fewer emergency repairs and reduced equipment replacements. This integrated strategy extends tower lifespans by 8–12 years while sustaining 99.98% signal continuity across 4G/5G networks.

Smart Monitoring Systems for Early Detection of Tower Defects and Anomalies

Common Defects in Communication Towers and Early Warning Signs

Environmental stressors like wind shear and ice loading contribute to structural degradation, with 46% of tower failures linked to undetected corrosion in steel joints (2024 Ground Movement Report). Early warning signs include unusual vibration patterns, metal fatigue cracks wider than 0.8mm, and foundation shifts detectable via interferometric sensors.

Automated Alerts and Diagnostics Through Connected Data Environments

IoT-enabled accelerometers and strain gauges feed data into centralized platforms, triggering tiered alerts—from SMS notifications for minor deviations to automatic shutdowns for severe anomalies. Wireless tiltmeters have been shown to reduce equipment failure response times by 32% through continuous real-time data streaming.

Integrated Sensor Networks for Accurate As-Built Status Monitoring

Deploying a combination of:

- MEMS-based inclinometers (precision: ±0.001°)

- Fiber-optic strain sensors (±2 microstrain accuracy)

- Multi-spectral corrosion detectors

enables 24/7 monitoring of tower integrity. This approach resolves 88% of discrepancies between design specifications and actual field conditions.

Leveraging Open Data Platforms for Proactive Anomaly Detection

By integrating tower telemetry with regional weather forecasts and maintenance histories, operators can identify emerging risk patterns. Open API architectures support predictive analytics that forecast bolt loosening risks 14–21 days in advance, achieving 94% accuracy in controlled trials.

Safety Protocols and Unified Solutions for Communication Tower Maintenance

Coordination Between Ground and High-Altitude Teams During Tower Maintenance

Seamless communication between ground crews and climbers prevents 62% of workplace accidents (OSHA 2023 Incident Analysis). Geofenced communication systems automatically mute non-essential signals above 300 feet, reducing radio interference errors by 41%. Wearable biometric devices now alert supervisors to cardiovascular stress in climbers 8.7 seconds faster than legacy monitoring methods.

RF Emitter Safety and Power Management in Live Network Environments

To comply with FCC-mandated exposure limits of 1.6 W/kg, precision power cycling is required during antenna repairs. Automated lockout-tagout (LOTO) systems reduce RF overexposure incidents by 57% compared to manual processes. New phase cancellation tools also enable safe maintenance on active 5G mmWave arrays, keeping surrounding emissions 22% below regulatory thresholds.

Compliance With OSHA and FCC Safety Standards in Tower Operations

Operators using AI-powered compliance platforms achieved a 94% audit pass rate in 2024 (Telecom Safety Benchmark). These systems evaluate 78 parameters—including fall protection ratings, galvanic corrosion levels, and ice load tolerances—against OSHA 29 CFR 1926 and FCC 47 CFR Part 17 standards. Third-party validation of safety-critical components occurs 4.2 times more frequently in compliant towers.

Customized Hardware and Software Integration for Multi-Vendor Tower Ecosystems

Cross-platform integration kits resolve 89% of legacy equipment compatibility issues through adaptive signal normalization (2023 Tower Interoperability Report). Universal power bus converters maintain ±0.5V stability across hybrid solar-diesel systems from 23 manufacturers, while machine learning algorithms predict vendor-specific failures with 92% accuracy 14 days in advance.

Table of Contents

- The Critical Role of Communication Towers in Modern Network Infrastructure

- Preventive and Predictive Maintenance Strategies for Communication Towers

-

Advanced Technologies Transforming Communication Tower Maintenance

- Use of Drones for Efficient and Safe Tower Inspections

- Thermal Imaging and LiDAR for Detecting Structural and Equipment Defects

- AI-Powered Analytics and Digital Documentation in Maintenance Workflows

- Digital Twin Technology for Real-Time Monitoring of Communication Towers

- Balancing High Initial Costs With Long-Term ROI of Automated Maintenance Systems

- Smart Monitoring Systems for Early Detection of Tower Defects and Anomalies

- Safety Protocols and Unified Solutions for Communication Tower Maintenance