What Are Remote Radio Units (RRUs) and Why They Matter in Base Transceiver Station Systems

Remote Radio Units or RRUs play an important role as transceiver parts within today's Base Transceiver Station systems. These units basically handle the conversion between digital signals and actual radio frequencies going both ways. When installed close to antennas at communication tower sites, they help cut down on signal losses that happen when using those long coaxial cables. Field research from around 2023 showed this positioning makes a real difference. Getting these units closer to where the signals need to go cuts power loss by about 25 to 30 percent over older arrangements. Better signal strength means networks run more efficiently overall. Plus it makes implementing new tech like 5G much quicker since there's less infrastructure to modify.

Integration of RRUs with Antennas and Baseband Units: Signal Flow Principles

RRUs link up with antennas using those short jumper cables we all know, while connecting to baseband units (BBUs) over fiber optic lines that run CPRI protocol among others. The setup moves the analog to digital conversion right into the RRU itself, which cuts down on signal delay and makes working on cell towers much easier for technicians. What's interesting is how one BBU actually handles several RRUs at once. This means most of the processing happens in one central location, but the actual RF signals get sent out from these remote units spread across different locations.

Trend Analysis: Shift Toward Distributed RRU Architectures in 5G Networks

Operators increasingly adopt distributed RRU layouts to meet 5G’s high-frequency spectrum demands. By deploying RRUs across tower sections rather than clustering them at the base, networks achieve wider coverage for millimeter-wave bands, reduced inter-sector interference, and scalability for Massive MIMO configurations.

Strategy for Minimizing Cable Length and Power Loss Using Strategic RRU Positioning

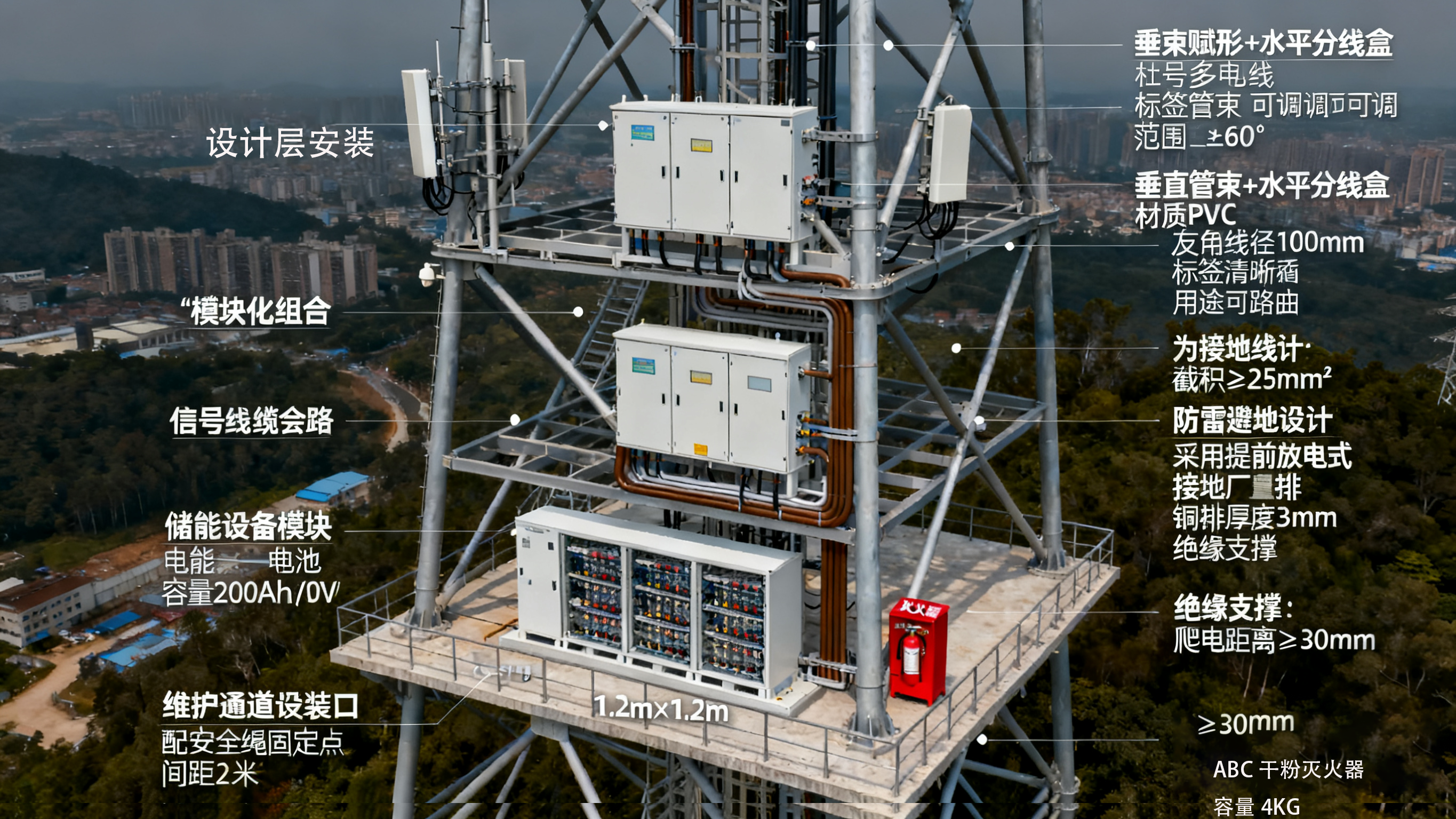

Optimizing RRU placement involves three key steps:

- Vertical Positioning: Mount RRUs within 3–5 meters of antennas to limit feeder cable losses.

- Fiber Prioritization: Use fiber-optic cables instead of coaxial lines for BBU-RRU connections, cutting signal attenuation by 90%.

- Modular Design: Group RRUs in standardized enclosures to simplify future hardware swaps.

This approach reduces operational costs by 18% while supporting compliance with evolving energy-efficiency standards.

Optimizing Power and Fiber Connectivity in Communication Towers RRU Installations

Minimizing Signal Attenuation in Fiber Runs from BBUs to RRUs

The fiber optic cables connecting baseband units (BBUs) to remote radio units (RRUs) typically experience around 0.25 dB loss per kilometer when using modern single mode fiber. However, poor installation practices can actually multiply that loss by three times what's expected. Good planning means keeping those RRUs no further than about 300 meters away from their corresponding BBUs so signals stay strong throughout the network. Sharp bends in the cable should be avoided entirely since anything past a 30 degree angle starts causing problems. For installations where distance becomes an issue, tower mounted amplifiers come into play. These devices help boost signals over longer distances, and many models feature modular components that let technicians tweak power output by roughly 10 percent every 50 meters along the run.

Efficient Power Delivery Systems for Remote Radio Units on Tall Structures

DC power systems typically supply around 48V or 60V to remote radio units (RRUs) with minimal voltage loss, often under 5%, thanks to smart load balancing techniques. This becomes really important when dealing with tall towers exceeding 60 meters in height. Switching from copper to aluminum conductors cuts down cable weight by approximately 35%, without sacrificing performance because these cables come with special anti-oxidation coatings that keep them conducting electricity effectively. For installation purposes, centralized power hubs equipped with 2N redundancy configurations can handle as many as twelve RRUs within each sector. The cost savings are substantial too, reducing expenses by roughly $18 per meter during setup, making this approach both technically sound and economically attractive for network operators looking to optimize their infrastructure investments.

Balancing Reliability and Cost in Power and Fiber Deployment

When combining aerial fiber for about 60% of the network with underground conduits along those really important sections, companies typically see around 98.5% system reliability while spending roughly 22% less than if everything was buried underground. Most operators find that automated load monitoring catches nearly 9 out of 10 potential power issues before they actually cause any service problems, which definitely helps keep yearly maintenance expenses down. And let's not forget about those pre-terminated fiber assemblies equipped with APC connectors. These save technicians a good chunk of time during installations, cutting down on labor hours by approximately 40% when compared to traditional field termination methods that require so much more hands-on work.

Thermal and Structural Management for Reliable RRU Performance

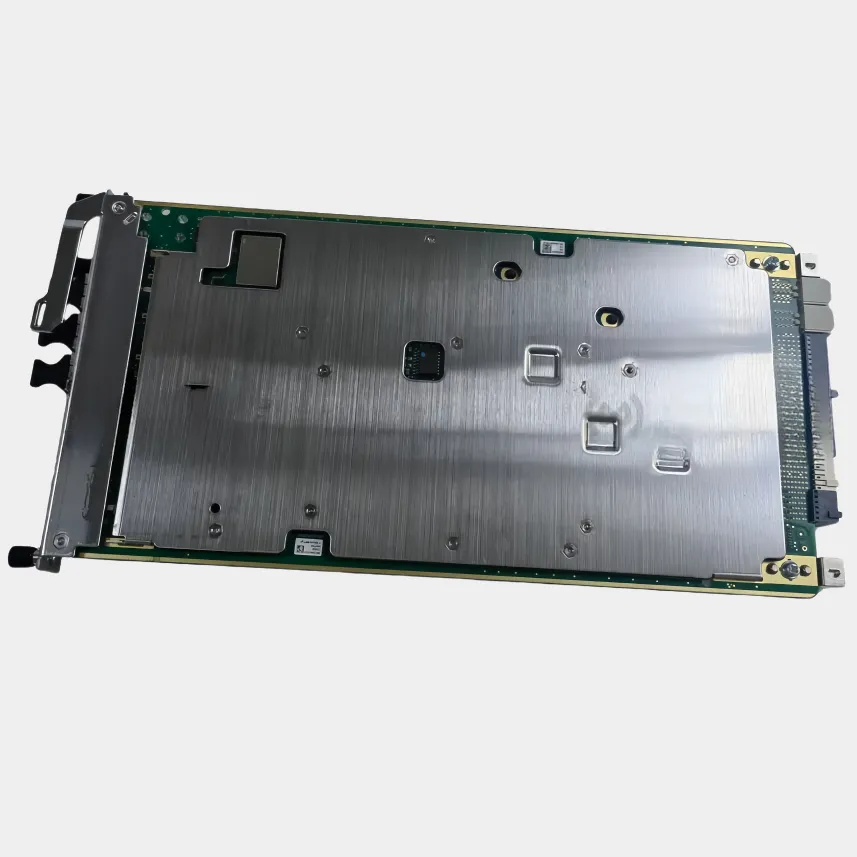

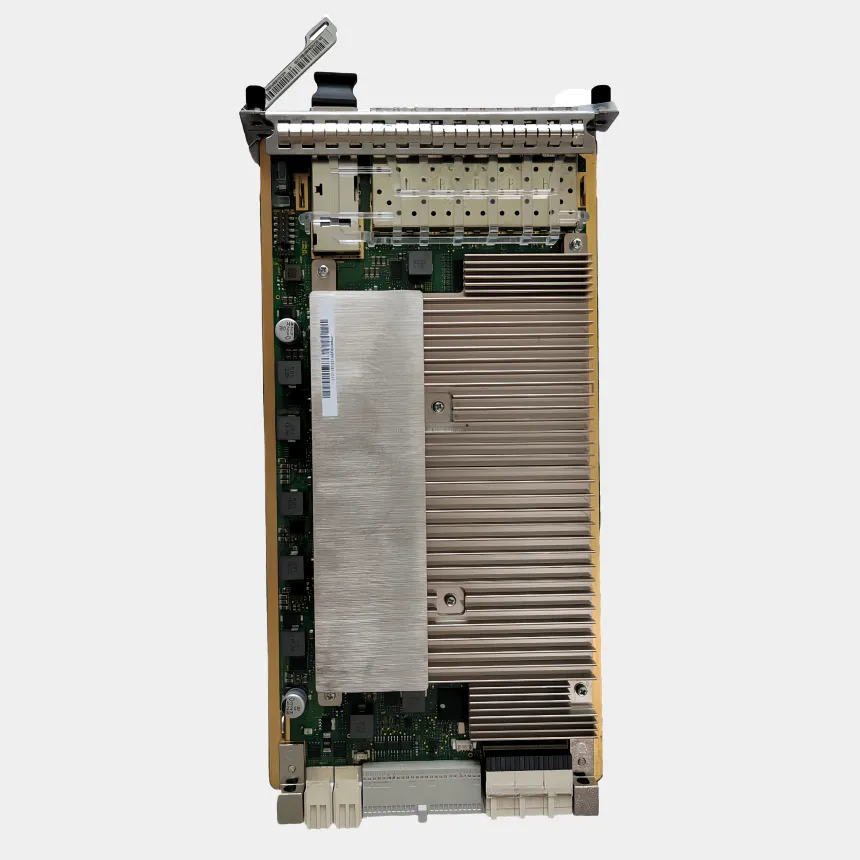

Heat Dissipation Challenges for RRUs Mounted on Communication Towers

Remote radio units tend to run pretty hot when they're working, especially outdoors where internal temps can hit over 60 degrees Celsius. If we don't manage this heat properly, things start going wrong fast. The equipment will throttle back on power output sometimes by as much as 30%, or worse yet, components just break down over time. Most modern setups mix passive cooling methods such as those aluminum heat sink blocks with active cooling through smart fans that kick in when needed. For installations in really hot regions, engineers need to factor in annual temperature changes that might swing by 40 degrees or more. Some recent research from last year showed interesting results too. Towers equipped with special connectors built to handle extreme weather saw around 18 percent fewer problems related to overheating than regular ones did.

Balancing Weight and Wind Load Across Tower Sections

A typical 3-sector 5G RRU cluster weighs 45–65 kg, requiring careful load distribution. Wind loads add complexity:

- Structural Limits: Steel lattice towers support up to 200 kg/m² at 150 km/h winds

-

Material Tradeoffs: Aluminum enclosures reduce weight by 25% versus steel but increase upfront costs

Best practices recommend positioning RRUs within the tower’s middle third, avoiding top-mounted configurations that amplify sway by 12–15%.

Data Insight: Failure Rates Linked to Poor Thermal and Structural Planning

Towers with suboptimal RRU layouts experience:

| Factor | 5-Year Failure Rate Increase | Maintenance Cost Impact |

|---|---|---|

| Thermal issues | 42% | $28k per incident |

| Structural stress | 31% | $19k per incident |

A 2024 analysis of 1,200 communication towers revealed that 63% of RRU replacements stemmed from preventable thermal or mechanical stressors, underscoring the need for proactive design validation.

Ensuring Maintenance Access, Safety, and Compliance in RRU Layouts

Effective communication towers RRU layouts require meticulous attention to maintenance workflows, safety protocols, and regulatory benchmarks. Below are critical strategies for optimizing these factors.

Core Principles of Equipment Layout for Operational Efficiency and Maintenance Access

When RRU setups focus on easy access, repairs tend to take about 25% less time than traditional layouts. According to field data from Knowpiping in 2024, organizing parts into standard module groups with at least 60 cm of space around them lets techs swap out broken components roughly 40% quicker. For vertical installations, it's important not to leave areas where nothing can be seen or reached. Horizontal arrangements need enough room so workers can get to panels without taking apart neighboring gear first. These practical considerations make maintenance jobs much smoother in real world situations.

Electrical Safety and Grounding Practices for Communication Towers RRU Configurations

Good grounding practices are critical for preventing dangerous arcing at base transceiver stations, particularly when storms roll through. Research from last year showed that sites implementing multi-path grounding saw about two thirds fewer electrical problems compared to standard setups. Keeping voltage differences under 5 volts between the RRU chassis and tower frame matters a lot too. To achieve this, technicians should place isolation transformers and surge protection devices no more than three meters away from equipment locations. This helps cut down on those pesky induction loops that can cause all sorts of headaches for maintenance crews later on.

Adhering to International Safety Standards and Regulatory Requirements

Compliance with IEC 62368-1 (hazard-based engineering) and ETSI EN 301 908-13 (5G RF exposure) minimizes liability risks. Non-compliant installations have 3.8x higher failure rates in extreme weather, per 2023 audits (IRPros). For cross-border projects, align designs with both FCC (US) and CE (EU) thresholds for electromagnetic compatibility.

Real-World Example: Reducing Downtime Through Standardized, Compliant Layouts

A European telecom operator reduced annual downtime by 30% after redesigning 1,200 tower sites using modular RRU layouts. By standardizing mounting heights, cable routing paths, and safety guardrail placements, average repair duration dropped from 90 to 63 minutes. The project cut operational costs by €18 per tower monthly while exceeding ETSI safety benchmarks.

Future-Proofing Communication Towers RRU Layouts for Scalability and Technology Evolution

Designing Flexible RRU Layouts for 5G and Beyond

Modern communication towers demand RRU configurations that support current 5G requirements while accommodating emerging 6G standards. Optimizing antenna positioning and fiber routing minimizes retrofitting costs during technology transitions. Modular mounting systems enable operators to swap hardware without structural modifications, ensuring seamless integration of advanced beamforming and massive MIMO technologies.

Case Study: Improved Signal Latency Through Optimized RRU Placement

According to a recent 2023 study on IoT scalability issues, one major manufacturer managed to cut down signal latency by around 30 percent simply by moving their remote radio units (RRUs) nearer to the actual antenna arrays. The company found that when they strategically positioned these components, the length of fiber optic cables needed decreased significantly. This meant less time for signals to travel through the network, which helped reduce those annoying propagation delays. Plus, they still stayed within all the ETSI thermal requirements for equipment safety. What does this mean in practice? Faster response times across the board! Real world benefits include better performance for things like self driving cars that need instant data processing and AR experiences where even milliseconds matter a lot.

Strategies for Scalable Upgrades Without Overhauling Existing Infrastructure

Future-proof designs prioritize standardized interfaces and excess power capacity (minimum 20% headroom) to support next-generation RRUs. Hybrid fiber-copper cabling allows gradual migration to full fiber connectivity as bandwidth demands increase. Decentralized power systems with smart load-balancing reduce dependency on centralized backups, enabling phased upgrades across tower sectors.

Frequently Asked Questions

What is the primary function of an RRU?

RRUs convert digital signals into radio frequencies and vice versa, reducing signal loss and improving network efficiency.

Why are RRUs positioned close to antennas?

Positioning RRUs close to antennas reduces power loss and enhances signal strength by minimizing the length of coaxial cables used.

How do RRUs connect with BBUs?

RRUs connect with Baseband Units (BBUs) using fiber optic lines to facilitate efficient data transfer and processing.

What challenges do RRUs face in terms of heat management?

RRUs generate significant heat, especially in high-temperature environments. Effective heat dissipation methods are crucial to prevent equipment degradation.

How can RRU layouts be future-proofed?

Flexible RRU layouts and modular designs help accommodate emerging technologies and facilitate seamless upgrades without extensive retrofitting.

Table of Contents

- What Are Remote Radio Units (RRUs) and Why They Matter in Base Transceiver Station Systems

- Optimizing Power and Fiber Connectivity in Communication Towers RRU Installations

- Thermal and Structural Management for Reliable RRU Performance

-

Ensuring Maintenance Access, Safety, and Compliance in RRU Layouts

- Core Principles of Equipment Layout for Operational Efficiency and Maintenance Access

- Electrical Safety and Grounding Practices for Communication Towers RRU Configurations

- Adhering to International Safety Standards and Regulatory Requirements

- Real-World Example: Reducing Downtime Through Standardized, Compliant Layouts

- Future-Proofing Communication Towers RRU Layouts for Scalability and Technology Evolution

- Frequently Asked Questions